A 2004 paper by Hod Lipson and Evan Malone was what inspired me to work in 3D printing. The two researchers later showed us that one could make a simple 3D printed robot with 3D printed batteries and actuators. They also developed the open source Fab@Home desktop printer in 2007. Both are a huge inspiration to me so when some of Hod’s papers started to veer off into soft robotics and resilient machines I took a long hard look at the emerging field.

And…I didn’t get it. Around 2010 I concluded that this was a lot of grant-giving for grant giving’s sake stuff. The only real useful application I could see were 3D printed pneumatic soft grippers. Super Releaser has an excellent history of soft grippers here. Soft grippers could make robots more capable of interacting with people and the world and I saw that as a very interesting development. Hod and others were looking to make the entire robot a soft robot, however. Soft bodies, soft actuators, soft sensors, soft everything. Some of the stuff seemed outlandish with chemical reactions powering pneumatic assemblies and many bioinspired robot fish. It didn’t help that most of this soft robotics stuff initially looked a bit hokey and contrived.

It took me years to come to grips with soft robots. I was sceptical for a very long time. I kept reading paper after paper. YouTube videos emerged as well as soft robotics GIFs but still, I thought that this was a detail or a fad. Then I had a thought: what if all the Sci-Fi robots were just silly imaginings made by authors looking to entertain? What if we were wasting billions developing humanoid robots that can walk up stairs just because those are in the movies? That would be insane right? Imagine there were billions of dollars in research funding going towards making Quidditch happen? All of this humanoid robot research is just plain silly. If countries were building a Death Star people would ask questions right? If billions were being spent on AT-AT walkers people would wonder, protest? But, whole industries, countries and tens of thousands of researchers are making C3PO happen and we don’t bat an eye? Look, I want real lightsabers as much as the next guy but we need to be rational. And this whole humanoid robot thing is just like AT-AT walkers and light sabres: cool but stupid, infeasible and unnecessary. It would be cheaper to make a new robot for every floor rather than one that could walk upstairs. Whats the business case for humanoid robots? Why are we developing them?

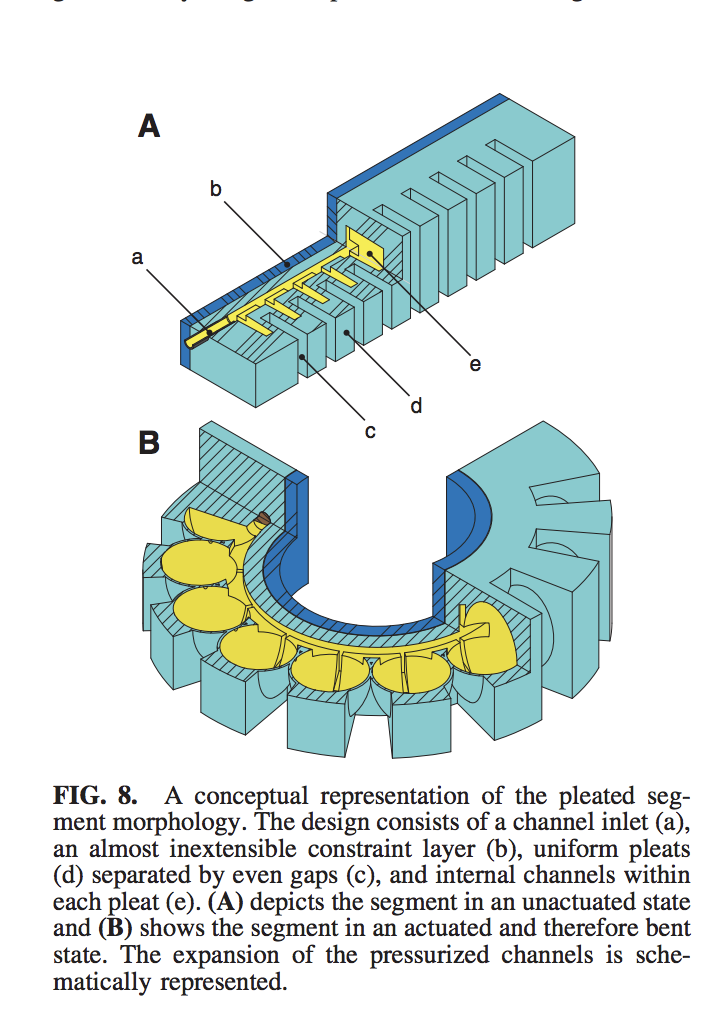

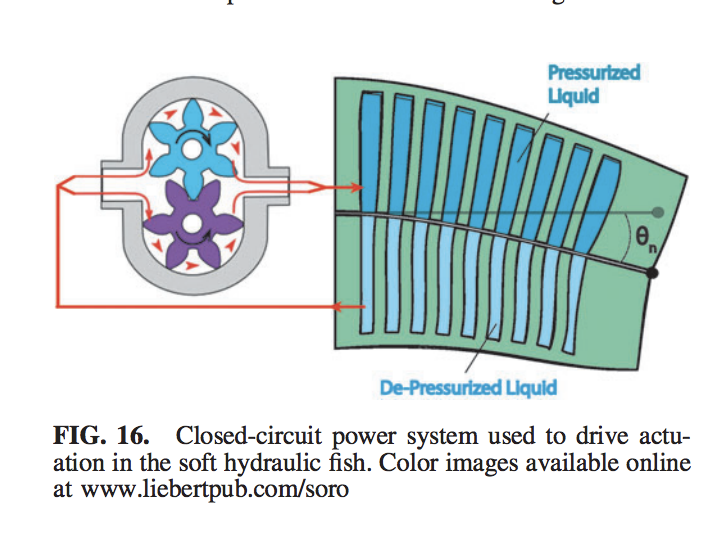

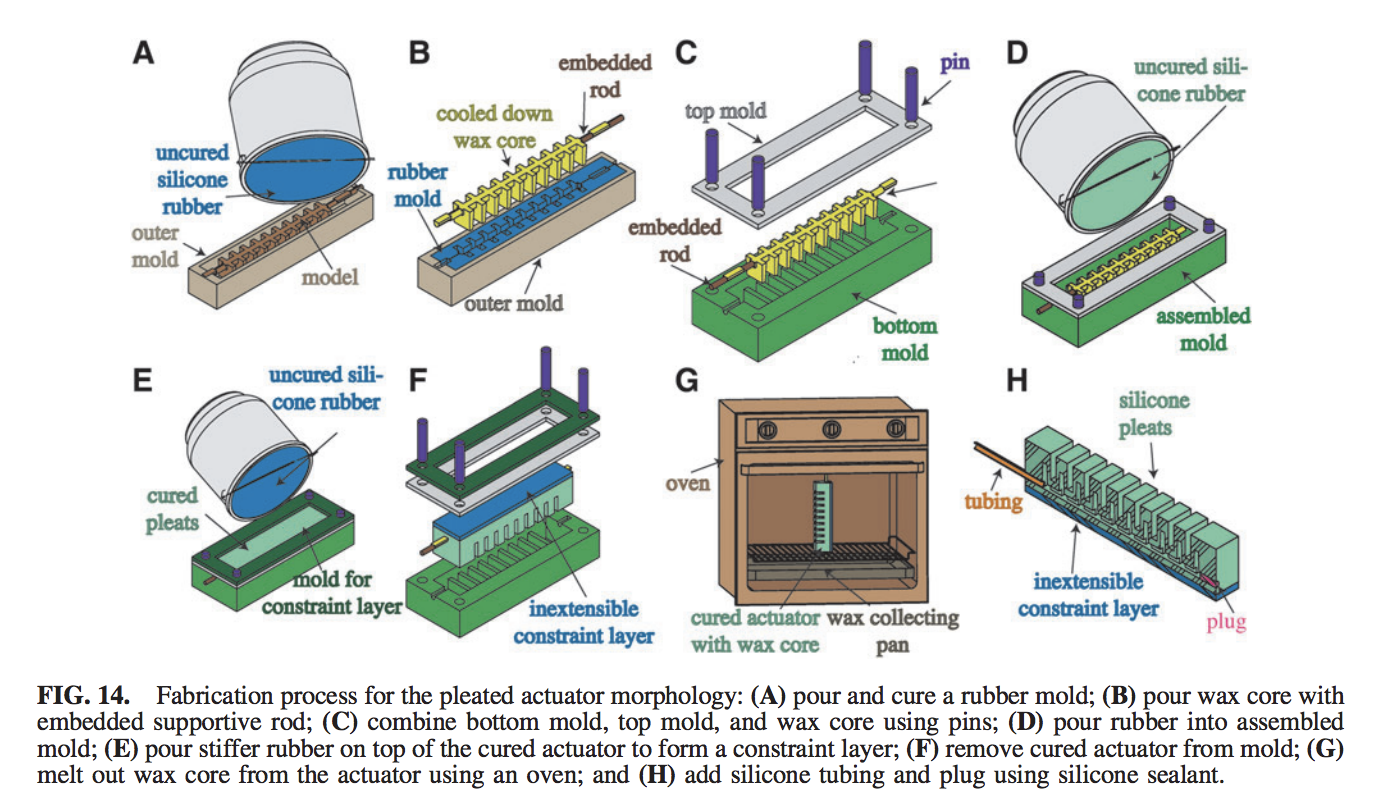

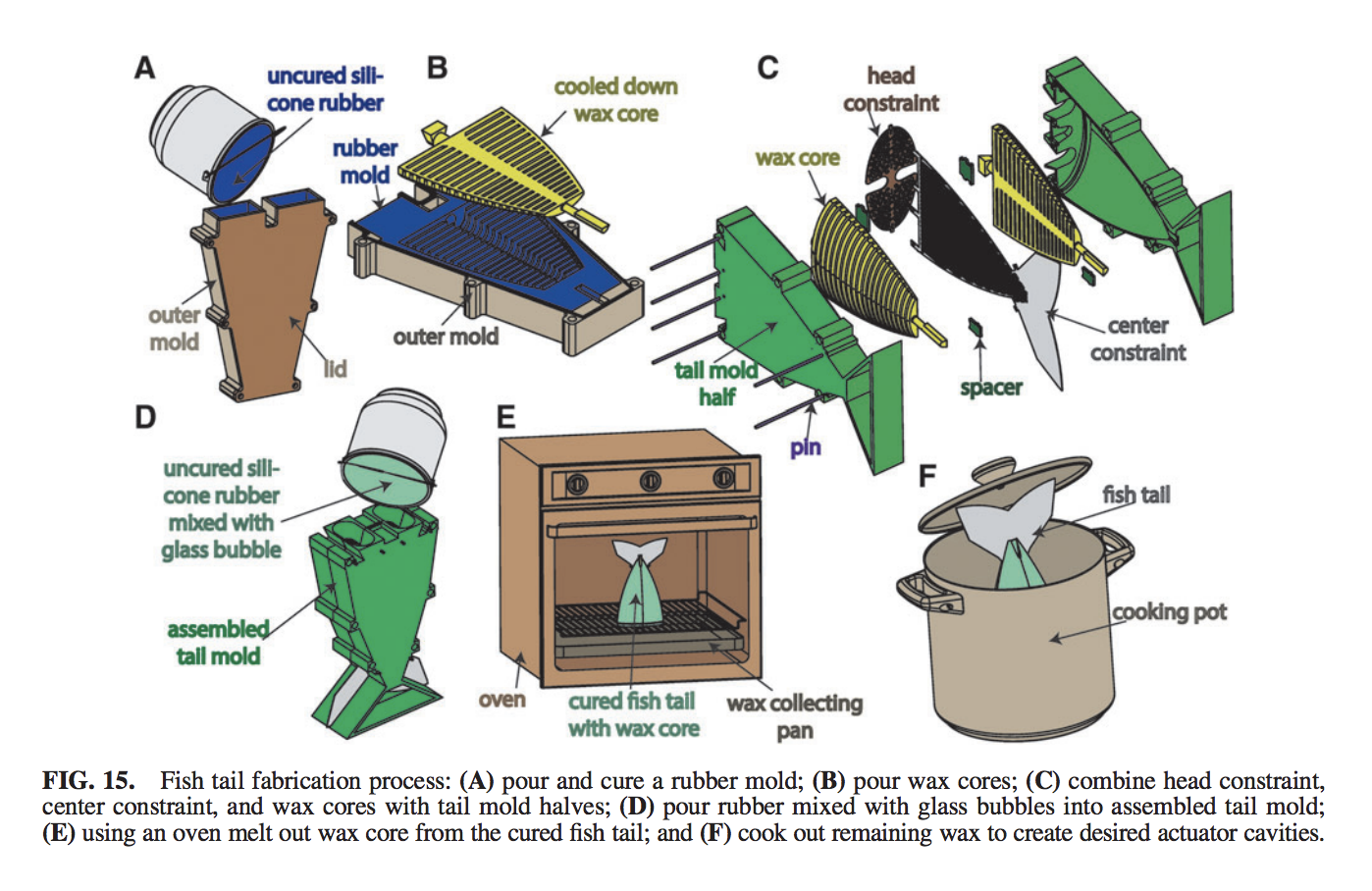

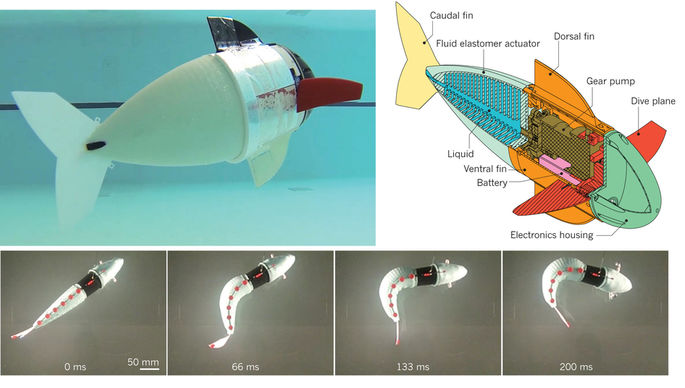

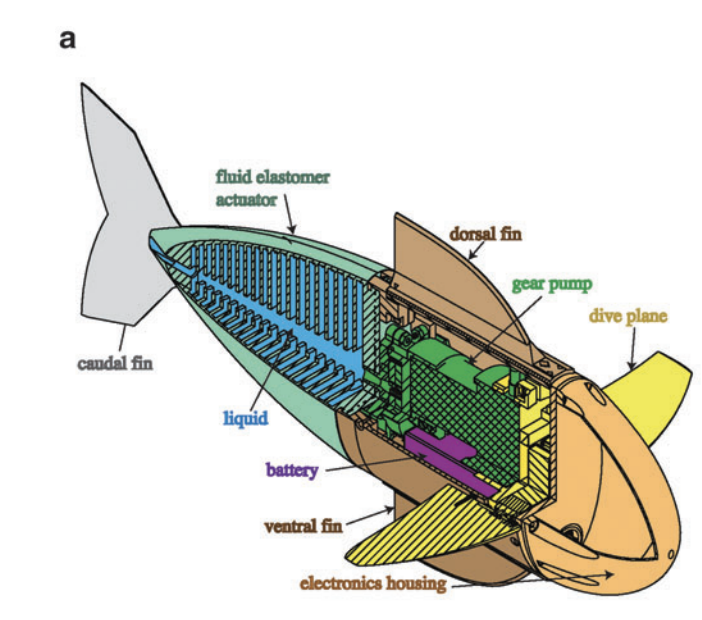

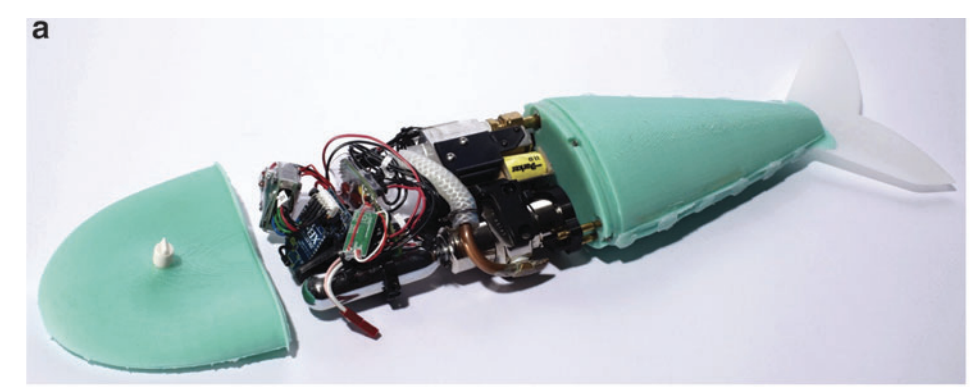

What if we dispensed with the humanoid robot idea altogether and instead think of functional robots designed for sets of tasks. What if we dropped the one universal Commander Data robot and instead thought of small cheap disposable robots that would live not in a novel but in the real world? Disposable bots, I called them in my mind. Not multi-million dollar Asimos teeteringly kicking a ball but cheap inexpensive robots that would disappear or be thrown away as soon as their task has been completed. Not billions spent making a robot that could walk like a human or some terrifying nightmarish Boston Dynamics Hound of Baskerville’s killbot but rather a descendant of the cheap omnipresent consumer electronics that surround us. If we see how fast consumer drones are developing and assume that chips and sensors will always get cheaper then what will the $5 robots of the future look like? Remember those cheap little RC helicopters that you could buy for $15 that’s the technology paradigm that interests me with regards to robotics. Below we can see a robot fish. This particular one was created by a team at MIT CSAIL as part of their soft robotics research. It describes several methods for making soft robots, in particular, a Fluid Elastomer Actuator. The design is ingenious but as we can see the multitude of fabrication steps required as well as the different materials and processes will make this cost prohibitive.

How would we be able to make the robot equivalent of Crocs? I always like to use Crocs as thought experiment fuel. The reason is that I could have never have come up with the idea for Crocs. The only way I could have come up with Crocs, was if the starting question is “how can I make the world’s cheapest shoes?” Or how can we make the least expensive shoes imaginable using molded closed cell foam (and later TPU)? So if we Crocsify robots we come up with a robot that would be made in one single production step out of the fewest number of parts or materials in that production step out of inexpensive materials. That one step would approximate the functionality created through many steps and materials in current devices. What would fit that technology path and outperform current technology at lower cost? And then, only then, did I go “Oh Fuck, soft robotics is totally going to be a thing.” 3D print all the robots, recycle robot, reprint new robot. No nightmare fuel Boston Hellhound but a purposeful efficient cheap printable soft robot. No national prestige project violin playing nonsensebot but rather you and I 3D printing robots at home.

I now understand that bioinspiration is a good thing and that in order to mimic nature more perfectly soft parts are required in many areas. I also understand that a flexible and soft robot could have very different use areas where it could outperform a rigid counterpart. I’m excited by self-configurable robots that can adapt to tasks or circumstances. It would be a breakthrough to have a robot powered by heat or through photosynthesis. The idea that robots would scavage for their own energy or be permitted to morph continually would be interesting as well.

The below robot uses 3D printing for circuits and a microfluidics.

Small robots in the bloodstream, unobtrusive robots for spying, cobots that are near people all the time could all benefit from soft robotics. Probably swimming robots that mimic fish will be far more efficient than conventional underwater robots and maybe robots that fly like birds or insects will be as well.

The Wyss Institute jumping robot uses 3D printed gradient materials.

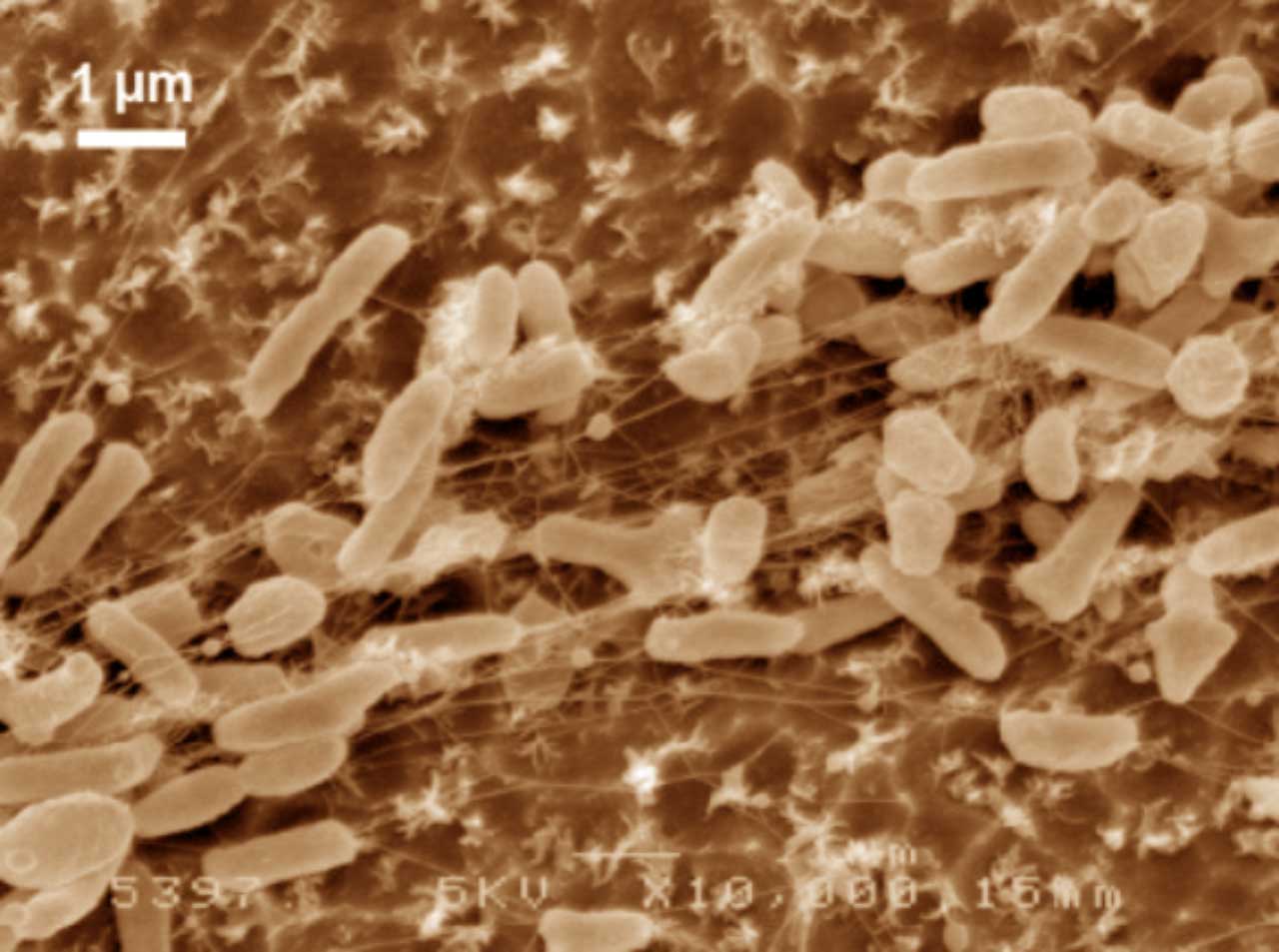

Nature takes a razor to fat. Shapes, structures and creatures in the natural world are very efficient. 30 Kilo of blubber is enough to power a Great White Shark for 11 days. Canada Geese eat around 1.8 Kilo of grass per day. A Goose can fly, is biodegradable and its waste is a Kilo of carbon per day. A soft robot design coupled with a biological energy creation mechanism could lead to a very efficient class of robot indeed. This class of robots would be power efficient and also environmentally efficient as well. A bioinspired design may make its form more efficient but a biological or chemical “engine” will also make the robot very efficient to operate. The resulting design will also be efficient in terms of its waste and end of life disposal as well. So not biomimicry to come up with a form but biomimicry across the lifespan of the device. The resulting robot would be ecological and bioinspired, soft and efficient. They would use bacteria, sunlight or harvesting to find energy. We could call them ecobibots. This would be a huge step forward in robotics development.

Bacteria are now being engineered to feed off waste or things such as methane. For a methane-rich environment, a methane harvesting soft robot could be very efficient. Want a sea patrol robot then perhaps it could feed off algal blooms? Want a robot for in the desert then maybe the huge fluctuations in temperature there could be used to power the robot via a kind of Stirling Engine.

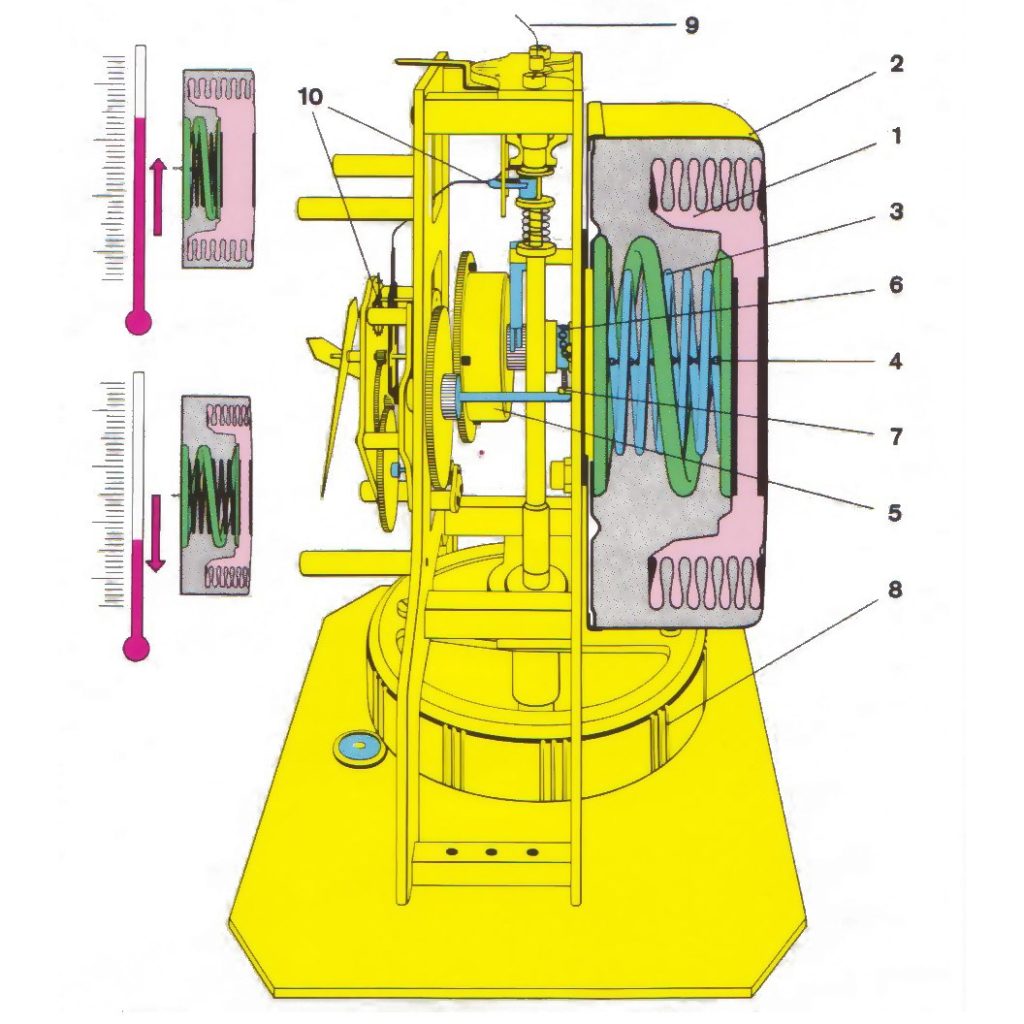

Regular temperature differences during the night and day could also be used to regulate or power chemical reactions in the robot to power it. Have you heard of Click Heat? It’s a sodium acetate heat pack. You click it and a reaction heats the pack, afterwards, you can boil it and then use it again. Wouldn’t that be a nifty kind of chemical mechanism to power a robot?

The Atmos is a clock by Jaeger Le Coultre that can perhaps work indefinitely. The Atmos works on temperature changes. A chamber filled with ethylene chloride gas in the clock expands and contracts in response to temperature fluctuations in your room. Expansion and contraction in turn wind the clock’s mainspring. Imagine a soft robot powered with a similar mechanism. Wifi signals abound and there are devices being made that let people harvest energy from these devices. Hydrothermal vents are surrounded by chemosynthetic bacteria that turn sulphur/hydrogen sulphide into food to sustain ecosystems on the ocean floor. Could we perhaps combine soft robots with chemosynthesis to obtain nutrients for the robot or indeed organic material that it could use to improve itself? And could we then pretty please use carbon dioxide as an input material?

The combination of new ways of generating power with soft robotics to create more efficient robots would mean taking biomimicry/biomimetics and using it to not optimize form but optimize energy usage. To make a soft robotics Asimo will take quite some time and a series of technological breakthroughs. But, what if we just need a soft robotics Roomba? Does that thing really need all those optics, batteries and a plethora of parts? What if we just had a Squeegee that gradually moved around our livingrooms picking up dust? No sensors, no chips just a Squeegee that moves by itself. Once a month you wash it under the sink.

In other applications: what if robots were cheaply spread around an oil spill and evolved in keeping with the task. What if these evolutionary and adaptive robots were easy to recycle? You could just continually recycle the ones that are not performing and let the others carry on. Many soft robots are being made through 3D printing. 3D printing continues to expand to make TPU, PCL, PA and other flexible materials possible. In other developments circuits and conductive materials can also be printed. 3D printing of magnets, technical ceramics and actuators also are being improved. Several soft robots have been entirely or almost completely 3D printed. 3D printing is the most obvious assembly and manufacturing technology for soft robotics. These technologies will continue to reinforce themselves and improve apace. Ever since my thought experiment I’ve become a true believer in soft robotics. Of course, this has to do with the things I’ve mentioned above but most of all with the fact that ecobibots, soft robots or their equivalents will be cheap.

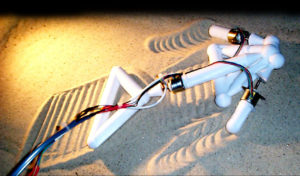

This soft gait robot was also made using 3D printing.

Soft robotics has the potential to make robots made in few manufacturing steps out of very inexpensive materials such as polymers. They’ll use fewer metals and less expensive materials and less material overall. Soft robotics has the potential to make robotics cheap. True ecobibots that would additionally procure their own power and be recyclable. In essence, you would have disposable robotics which would also lower costs. I finally believe in soft robotics but not because it could be revolutionary but because it can be cheap. If we look at developments in 3D printers and 3D printing materials soft robots could also be manufactured by the hundreds of thousands of desktop 3D printer operators worldwide and that would be very exciting indeed.

This shape memory coil and 3D printed soft robot was optimized for low cost manufacturing.

So far, however, most soft robots are conceptually amazing but seem to serve no purpose other than to demonstrate soft robotics. In order to really let soft robotics hit home, a useful soft robot would have to serve some purpose. It should also seem like a complex but easy to explain breakthrough. This after all, with a few million in PR money, was how the “3D printing revolution” happened. So we need a soft robotics demonstrator that would play well on Buzzfeed and top ten lists. Sad perhaps, but without adequate demonstrators of the capability of this technology, will remain dormant. Real wide interest will come once media can convince people that this is something relevant for the consumer right now. Once this occurs then we can speak of a Soft Robotics Revolution. So what say you? Let’s have at it? I’m a believer now, just registered the domain name: softroboticsjobs.com